Kinder Morgan – Engineering for Plant Expansion

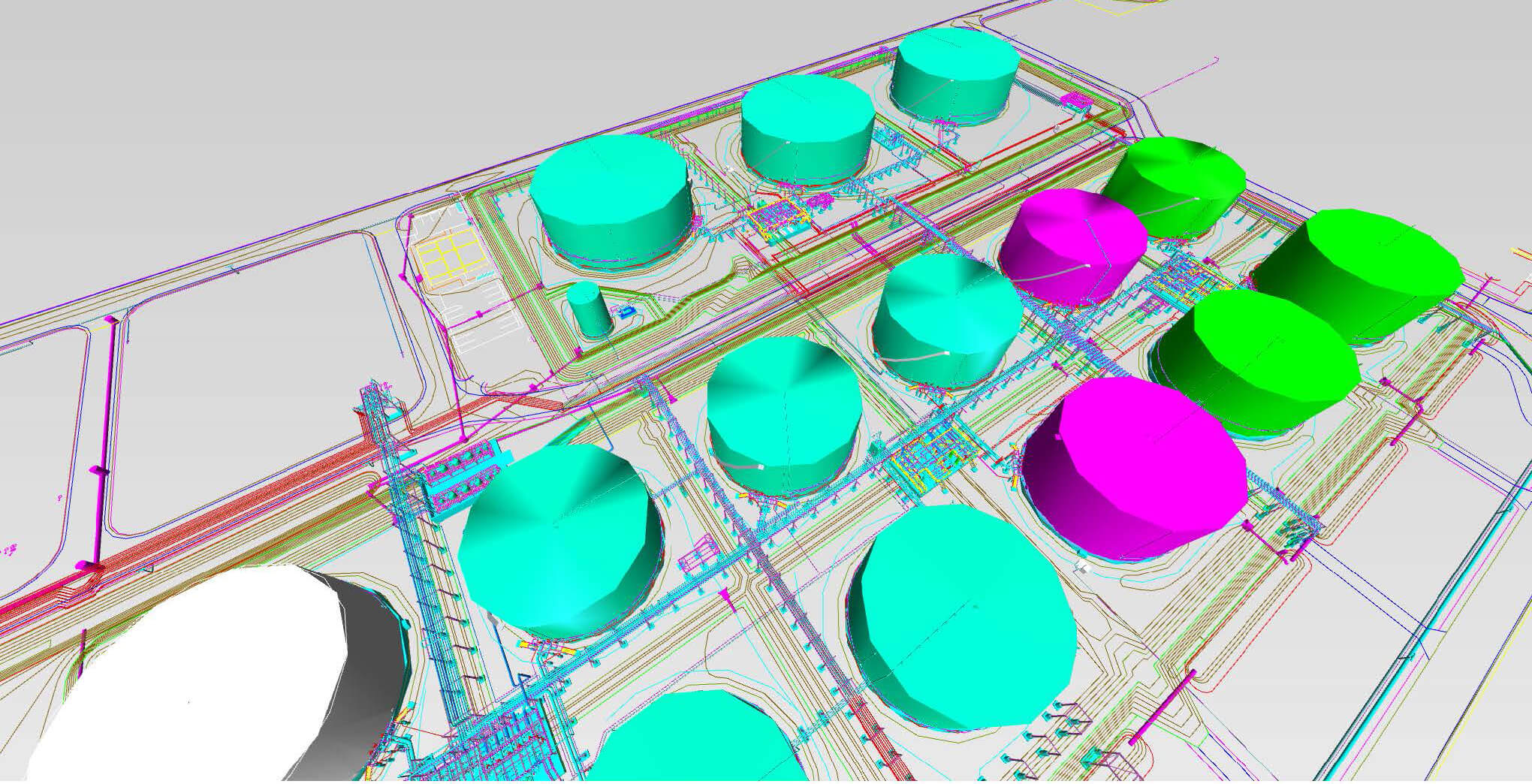

Matrix PDM Engineering provided engineering and design to add (15) new produce and feedstock tanks at the Kinder Morgan Galena Park terminal.

The tanks included (4) 200,000 bbl feed tanks, (3) kerosene tanks, (3) naphtha tanks, (2) diesel tanks, and (3) AGO tanks, each 100,000 bbl. This expansion allows NGL condensate liquid to be piped inbound by a 20-inch pipeline to the feed tanks, pumped through two splitter units for NGL processing to the respective storage tanks, and then exit the facilities via a manifold and pumps to a UG pipeline to the facility battery limit where the product is then transferred to existing storage tanks in the facility.

Pre-commissioning and commissioning included instrument calibration, coordination of utilities, functional testing, performance testing, and site acceptance.

Scope of Work

- Rockwell Automation ControlLogix architecture and processor

- Control system design drawings with I/O and remote panels, motor/actuator control schematics

- Emergency Shutdown (ESD) circuits, connection to field instruments, loop diagrams, network, and connection details

- Network design with failure tolerant ring topology for critical systems

- Control and metering of product from storage to on-site “splitter” refinery

- Connection to owner’s enterprise inventory management system for control of truck unloading operations

- Fire detection/suppression system connected for alert of client operations personnel

- Wonderware HMI screen and faceplate configuration based on owner’s object library with real-time and historical trending

- Distributed mobile tablet-based display architecture with a location-relevant graphics presentation

- Equipment procurement/panel supply and in-house simulation and factory acceptance testing performed