DESIGNING FLEXIBLE TERMINALS

Katherine Smith, Matrix PDM Engineering, USA reviews the demands of designing cement terminals across the globe and why providers must shift with the evolving needs of the industry.

Population increases, shifts in geographic distribution, and transportation infrastructure repairs and expansion often create uneven global demand for cement. Regional market activity can also vary significantly, resulting in disproportionate local cement supply. Against this backdrop, cement distribution terminals must be well-planned to achieve operational efficiency and flexibility and as a result, remain competitive.

This means considering the proposed service life of the terminal, ship sizes and water depth requirements, unloading/ receiving and transfer equipment rates, and storage capacities. Moreover, it means understanding and taking into account operational and logistical conditions

such as local costs and environmental constraints. Important factors to consider are discussed below.

Modes of transport

Efficient terminal design considers the best mode of transportation for loading and receiving cement. Water access, local rail infrastructure and roadway traffic constraints will impact design considerations for the operations and logistics. Local demand and distribution distances are other key factors that will influence transportation decisions.

Ship and barge

Moving cement by waterway offers substantial flexibility, can help ensure safe and timely delivery and allows for transportation of large volumes that would otherwise be too costly or logistically prohibitive with truck or rail-based transportation. Ship-based transport also opens supply chain access to cost-effective domestic and international markets.

This flexibility can create a significant competitive advantage in markets with limited local production or where regulatory requirements make permitting new production impractical.

Rail and truck

Trucking cement allows suppliers to transport product to the local market

or from an inland cement plant to a distribution terminal. Most deliveries to ready-mix clients are performed by truck due to the extreme flexibility and speed offered by this mode of transport. Trucking also offers a fast and lower capital cost option for bulk cement transfer to growing markets that cannot yet justify a larger capacity solution.

As overland transfer capacities and distances increase, some facilities may choose to transport by rail. This allows for shipment of higher volumes per railcar versus a truckload and can be more reliable over a long distance with less traffic concerns. That said, transporting cement by rail requires more planning and capital investment, which must be weighed against operational savings for high-volume transport over medium- to long distances.

Flexible storage

New terminals or expansion projects should evaluate storage types that best meet logistical needs and consider flexible storage options for throughput and different product mix or segregation.

Additionally, storage decisions may be affected by geotechnical constraints, seismic conditions, site configurations, and space limitations. The selection of storage options will also impact the need for additional equipment and manual operation required to operate the facility, as well as logistic and traffic options for shipping and receiving of materials.

Concrete silos

Concrete silos are a prime option for terminals looking for large-capacity storage, low operating cost, automated operation, and efficient drive-through direct truck loading. Silos also offer lower initial cost, low maintenance costs and reduced energy consumption, and typically require a smaller geographic footprint. Conversely, land conditions must be able to support the higher loadbearing requirements of a concrete silo. Concrete silos also typically need more design and construction oversight.

Steel silos

Bolted or welded steel silos can be cost-effective, faster to erect, and allow for easier incorporation of features such as doors and ladders. They have less complex foundation requirements and respond better in earthquakeprone regions. Steel silos can also be elevated above truck load-out lanes for reduced truck handling time. Facilities will often use steel silos for lower quantity or specialty product storage, combined with domes or concrete silos for large bulk storage.

Domes

Domes allow for large volume storage in areas that might not be ideal for silos such as those with mediumto poor soil conditions or high seismic or wind activity. Domes also offer the benefit of rapid construction regardless and require less development time to be spent on structural design details.

Dome storage does require careful consideration for reclaim operation, weighing long-term operating and maintenance costs against initial capital investment. Domes are also typically limited to single product storage which can impact flexibility in terms of product mix for the facility.

Flat storage

Flat storage is among the lowest capital cost options for cement storage. However, the cost savings can be offset by requirements of a larger storage footprint, higher operating cost due to manual reclaim and the need for more staff.

Flat storage may also present challenging working conditions and safety issues for staff operating manual reclaim in an enclosed, dusty environment.

Recent US cement terminal project highlights

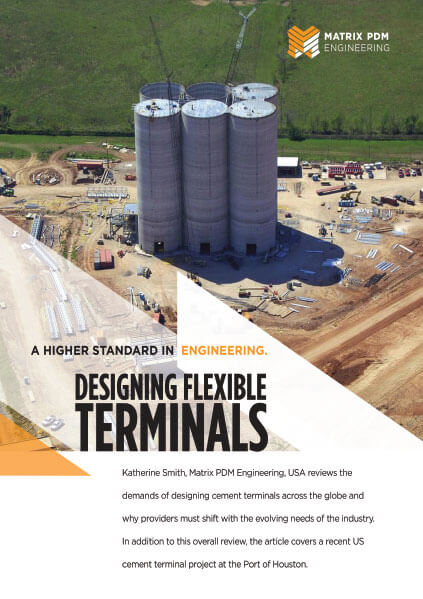

Truck lane addition at Houston Cement’s Port of Houston facility Houston Cement Co’s cement terminal at the Port of Houston is a state-of-the-art facility originally designed to import and distribute l.SMta of cement. It features six 56.7m (186ft) concrete silos and, at initiation of operations, the largestcapacity cement ship unloader installed in the US.

Initially, the owner had requested a dome storage-based facility with Matrix PDM Engineering (then River Consulting) providing final design, including civil, structural, mechanical and electrical systems for the greenfield facility. Major equipment procurement as well as silo design and automation, including programming and commissioning, were also part of Matrix PDM’s scope of supply.

During the bidding phase, Matrix PDM, together with the third-party construction contractor, developed an alternative silo storage solution to better use the site and provide a more ideal solution for logistics and long-term operations. The alternative solution also resulted in significant cost savings. The result was a custom design featuring 100,000t of storage and three lanes of automated truck load out with loading rates of S00tph, all designed to meet the customer’s operational goals.

Matrix PDM continues to partner with Houston Cement to optimise the design, operation and maintainability of the facility. The Matrix PDM electrical and controls team added enhanced diagnostics and troubleshooting features to the control system to help the operators isolate faults and more quickly restore operation after an upset condition. Real-time bearing temperature monitoring for critical components were also installed, allowing for advanced detection of failure in support of the owner’s preventative maintenance programme to minimise unplanned shutdowns. Other minor studies have also been performed and equipment has been integrated to keep the facility optimised.

Most recently, a fourth truck lane was added to the terminal to serve more customers during critical peak loading periods. As part of the project, a recirculation system was also added to two of the existing silos to further increase facility flexibility. The project included a new truck load-out structure, a transfer tower, air-gravity conveyors, platforms, a truck scale, load-out spout positioner, piping and a dust filter. Electrical and controls system programming was also provided to tie the new addition into the existing operating system.

A new terminal for GCCM at Port of Corpus Christi

At the Port of Corpus Christi, GCCM identified an opportunity to supplement cement supply and, as a result, Construction Engineering Consultants, the owner’s engineer, contacted Matrix PDM to provide engineering and construction support services for the cement import terminal.

Matrix PDM prepared preliminary layouts for the proposed project site within the Port of Corpus Christi. However, because of the proposed site’s location inside the secured area in the port’s new master plan, the port requested that GCCM consider alternative sites that could be fenced off and accessed outside the secured area. After reviewing and preparing conceptual layouts for several alternative sites, the owner ultimately decided on use of the current site. However, the terminal was designed to allow direct access and operations by both truck and rail without having to route traffic through security or interrupt port activities.

Matrix PDM provided study phase services, as well as preliminary and

final design, including structural, mechanical and electrical systems for

the greenfield facility. Silo design and automation, including programming and commissioning were also part of the scope.

The terminal is fully automated with ship and rail receiving, as well as truck and rail load-out. It features five 62.Sm (205ft) concrete silos with 84,000t of storage capacity.

In connection with the terminal, the port also contracted with Matrix PDM to provide conceptual layouts and designbuild RFQ documents for the new dock.

The GCCM Cement import facility’s fullyautomated systems provide an effective state-of-the-art process for cement unloading and loading at the terminal. Cement is delivered via Handysize ships at the 207m (680ft) dock and received via a rail-mounted Siwertell ship unloader with a rated capacity of lS00tph. The cement is then distributed to the five silos via a 1900tph inbound conveyor belt, bucket elevator and air gravity conveyor distribution system.

Construction of the facility commenced in 2018 and Matrix PDM continues to provide construction support for the project as well as equipment selection reviews, start-up and commissioning.

Designing for current and future flexibility

In a dynamic market where multiple factors will continue to impact the global demand for cement, those in the industry will need to be highly strategic when making decisions on the facility location, supply logistics, and other aspects of the production and distribution systems. Terminal designs that have taken into account all the factors for current needs and have consciously planned for future flexibility will best position cement companies to rapidly respond to changing market conditions.