Ammonia

AMMONIA CAPABILITIES

Matrix Service Company and its subsidiaries are staffed by dedicated, experienced engineer and construction professionals with expertise in the areas of conceptual design and feasibility studies, Front End Engineering and Design (FEED), detailed design, engineering and construction, integrator of production and liquefaction, commissioning, and ongoing maintenance and repair of ammonia storage facilities.

As standards committee participants, Matrix teams develop industry codes for project requirements through their representation on major committees such as ACI 376 and API 620, as well as experience with facility owners. Matrix is an expert in storage tank and facility design, procurement, fabrication and construction requirements, and safety practices associated with LNG and refrigerated liquids.

With 65 years of legacy experience, you will benefit when partnering with Matrix, with our start-to-finish deliverables spanning technologies and engineering, procurement, fabrication, construction, and maintenance services for the fulfillment of ammonia storage and production facilities.

The demand for ammonia used for fertilizers and as a hydrogen carrier will continue to increase, creating opportunities for producers all around the globe. Matrix has the critical resources for end-to-end coordination and provision of ammonia storage projects. What’s more, we have deeper resources than many smaller contractors, enabling us to see projects through to completion safely, on time, on spec, on budget, and with the quality you expect. We are also more streamlined than many larger providers, with the ability to move quickly and adapt to your needs. Detailed reporting and predictive forecasting help control costs and enhance accountability.

Matrix has proven experience in engineering, procurement, and construction of ammonia storage facility projects. Within the U.S. and Canada, Matrix is a full solutions EPC provider. Internationally, we partner with equally revered construction providers.

As a world-renowned leader in cryogenic and refrigerated storage terminaling solutions, we ensure the integrity and safety of your ammonia facilities. Matrix has successfully delivered an extensive list of diverse industry-leading storage and balance-of-plant solutions for ammonia projects and is excited to continue expanding into this division of critical work.

Ammonia services:

• Conceptual design and feasibility studies

• Front End Engineering and Design (FEED)

• Detailed design

• All solutions provider for engineering and construction

• Integrator of production, liquefaction, and storage facilities

• Commissioning of ammonia storage facilities

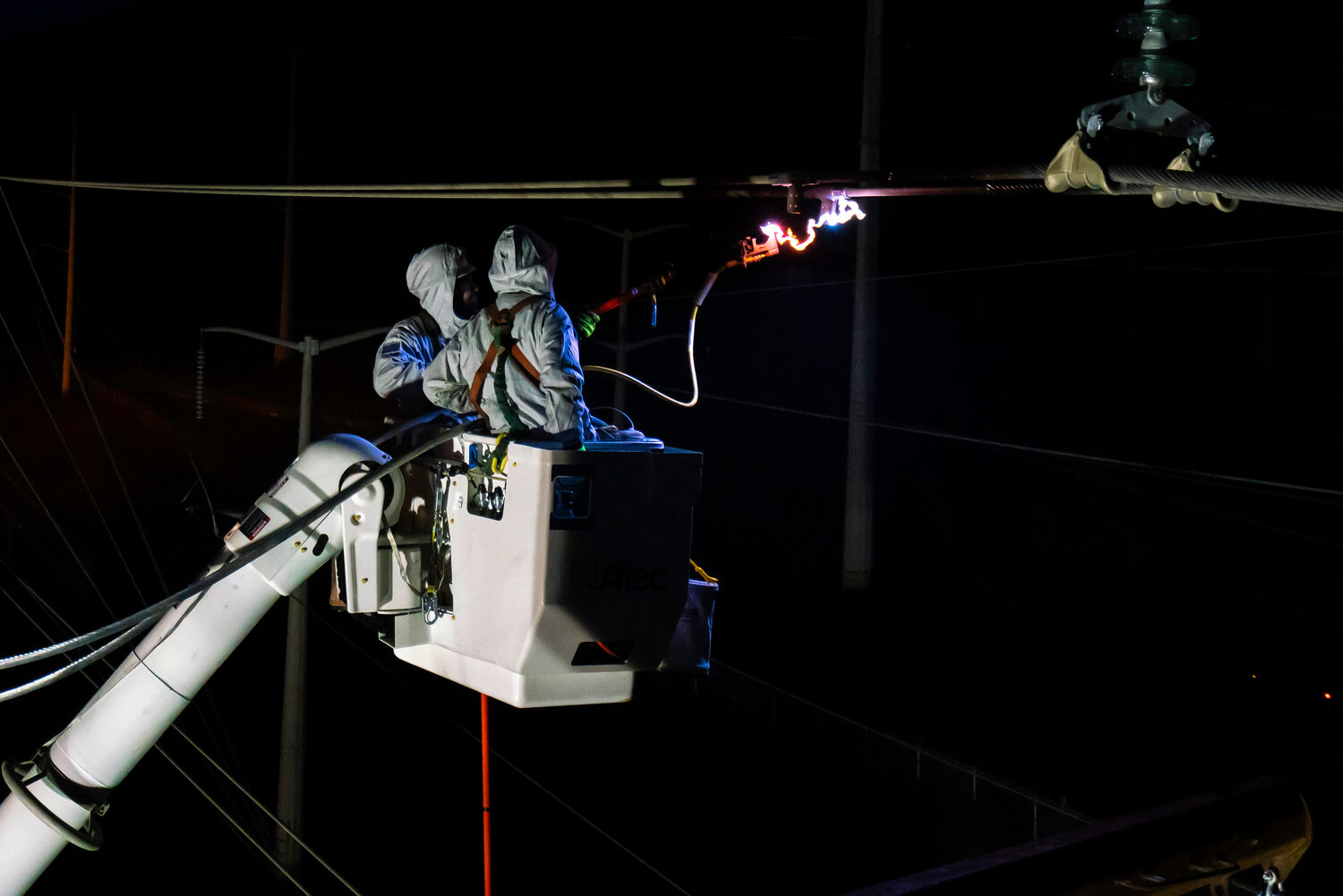

• Ongoing maintenance and repair of ammonia storage facilities

IN THE NEWS

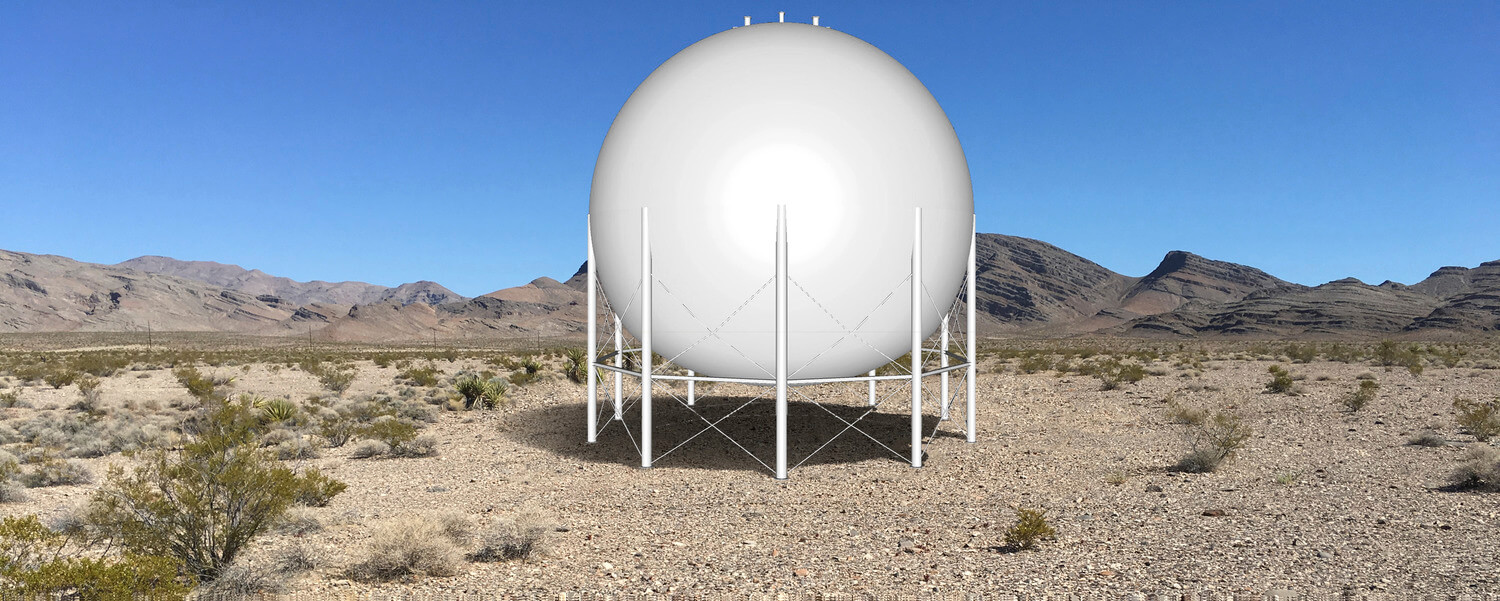

Matrix performed the engineering, procurement, fabrication, and construction of a 20,000-ton ammonia tank for Fortigen Geneva LLC’s anhydrous ammonia fertilizer manufacturing plant in Geneva, NE. The plant is Fortigen’s first manufacturing facility and produces 100 tons of anhydrous ammonia per day. This facility takes advantage of the low cost of natural gas and reduced transportation costs to serve some of the most productive cropland in the world. constructing cryogenic and pressure storage vessels, terminals, and related balance of plant facilities. READ MORE HERE